Top 8 Benefits of CMMS: Why Your Facility Needs a Computerized Maintenance Management System

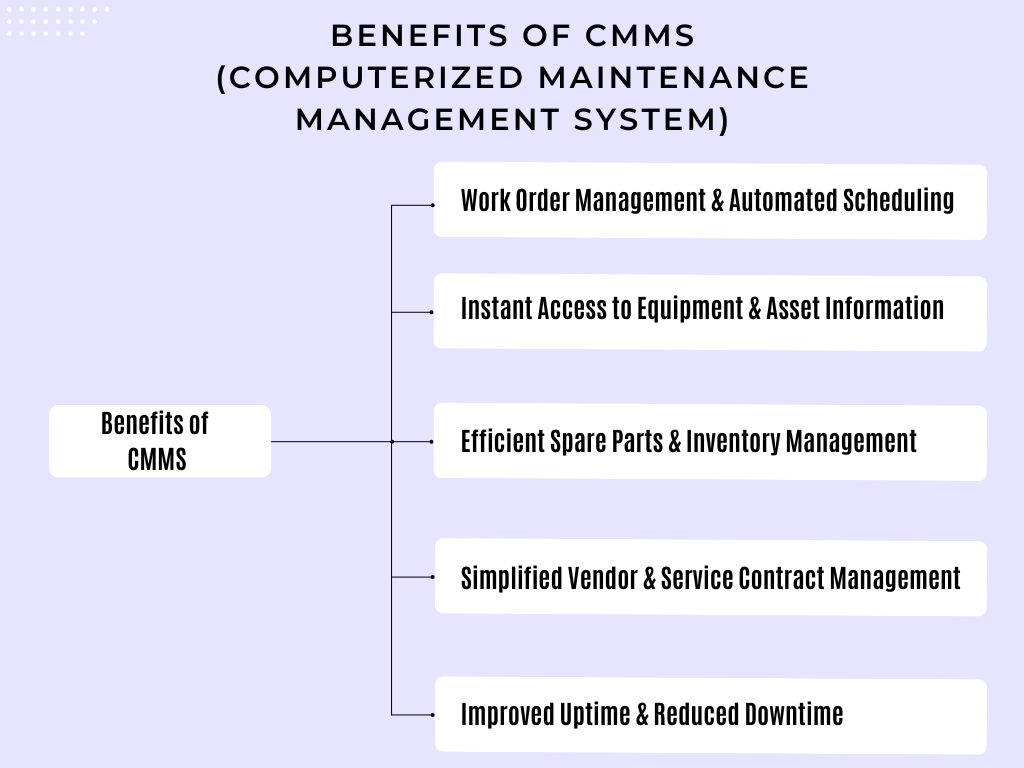

A Computerized Maintenance Management System (CMMS) goes beyond digitizing maintenance—it transforms how industrial operations and facilities run. From reducing unplanned downtime to improving production output, the benefits of a CMMS stretch across every layer of your organization.

In this blog, we explore the top advantages of implementing a modern CMMS and how it can revolutionize your maintenance strategy.

1. Streamlined Work Order Management & Automated Scheduling Say goodbye to clipboards and spreadsheets. A CMMS software centralizes work order creation, tracking, and execution, making maintenance operations more efficient and traceable.

Key CMMS features include:

- Centralized work order requests and history tracking

- Automated work order creation triggered by sensor data or usage metrics.

- Job prioritization for critical equipment

- Mobile CMMS access for real-time updates on the go.

This reduces paperwork, improves task accountability, and allows managers to allocate resources effectively—boosting overall technician productivity.

2. Instant Access to Equipment & Asset Information Maintenance teams rely on accurate and timely data to make informed decisions. A CMMS provides real-time access to essential asset data:

- Centralized equipment history and documentation

- Access to manuals, SOPs, and troubleshooting guides

- Visual dashboards showing asset performance and health

- Integration with IoT devices for real-time KPIs and condition monitoring.

Faster access means quicker diagnostics, better repairs, and minimal downtime.

3. Preventive Maintenance Scheduling Made Easy One of the biggest benefits of CMMS is its ability to automate and optimize preventive maintenance (PM) schedules. This helps extend asset life, minimize sudden breakdowns, and improve equipment reliability.

A CMMS supports:

- Recurring PM scheduling by time, usage, or condition

- Customizable plans per asset or location

- Automatic reminders and technician assignments.

This ensures no critical maintenance is missed and that all work is done proactively rather than reactively.

4. Efficient Spare Parts & Inventory Management Avoid stockouts and emergency purchases. With CMMS inventory management, you get complete visibility into spare parts and consumables:

- Real-time stock levels and reordering alerts

- Parts usage linked directly to work orders

- Insights on procurement and inventory cost control

Better inventory planning means lower holding costs and faster repairs due to part availability.

5. Simplified Vendor & Service Contract Management Modern CMMS platforms make managing vendors and service contracts easier and more transparent:

- Central storage for service contracts, SLAs, and vendor details

- Controlled user access based on role and scope

- Automated alerts for contract renewals and service schedules

- Vendor performance tracking and cost analysis

This improves collaboration with third parties while reducing administrative overhead.

6. Improved Equipment Uptime & Maintenance Team Productivity A core benefit of a CMMS is maximizing equipment uptime through proactive strategies and efficient resource management:

- Quicker fault resolution with accessible documentation

- Reduced breakdowns from preventive practices

- Real-time dashboards for workload balancing

- Recognition tools for tracking team KPIs

This results in fewer disruptions, smoother operations, and empowered maintenance teams.

7. Reduced Downtime and Maintenance Costs Unplanned downtime can severely disrupt production and increase operating costs. A CMMS helps reduce this through:

- Preventive maintenance workflows

- Failure trend analysis to avoid repeated issues

- Centralized service logs for smarter planning

- Centralized service logs for smarter planning

By reducing emergency repairs and operational disruptions, facilities save money and improve production continuity.

8. Be Audit-Ready: Ensure Compliance and Workplace Safety A CMMS helps industrial businesses meet regulatory and safety requirements without stress:

- Digital records of all maintenance and safety procedures

- Stored SOPs, LOTO checklists, and compliance reports

- ROn-demand generation of audit-ready documentation

- Historical insights for spotting safety and maintenance trends

With these tools, your facility is always audit-ready and operating under the best safety standards.

Conclusion: Why Invest in a CMMS?

A Computerized Maintenance Management System is not just a maintenance tool—it’s a strategic asset that empowers your facility to achieve operational excellence. From improving technician efficiency to minimizing costly downtime, a CMMS drives productivity, accountability, and performance.

Whether you’re managing a manufacturing plant, facility services, or utilities infrastructure, investing in the right CMMS solution can transform your maintenance department from a cost center to a value driver.